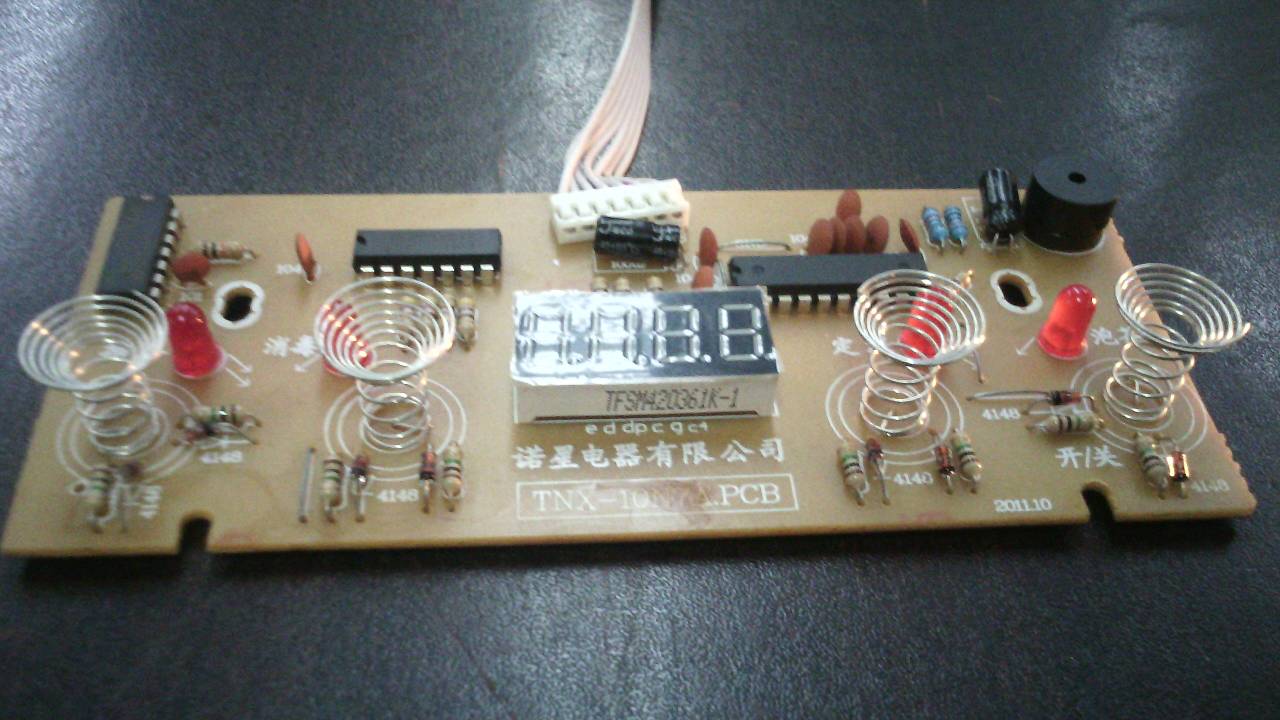

High-Conductivity Koporo Terminals bakeng sa PCB Soldering Likopo

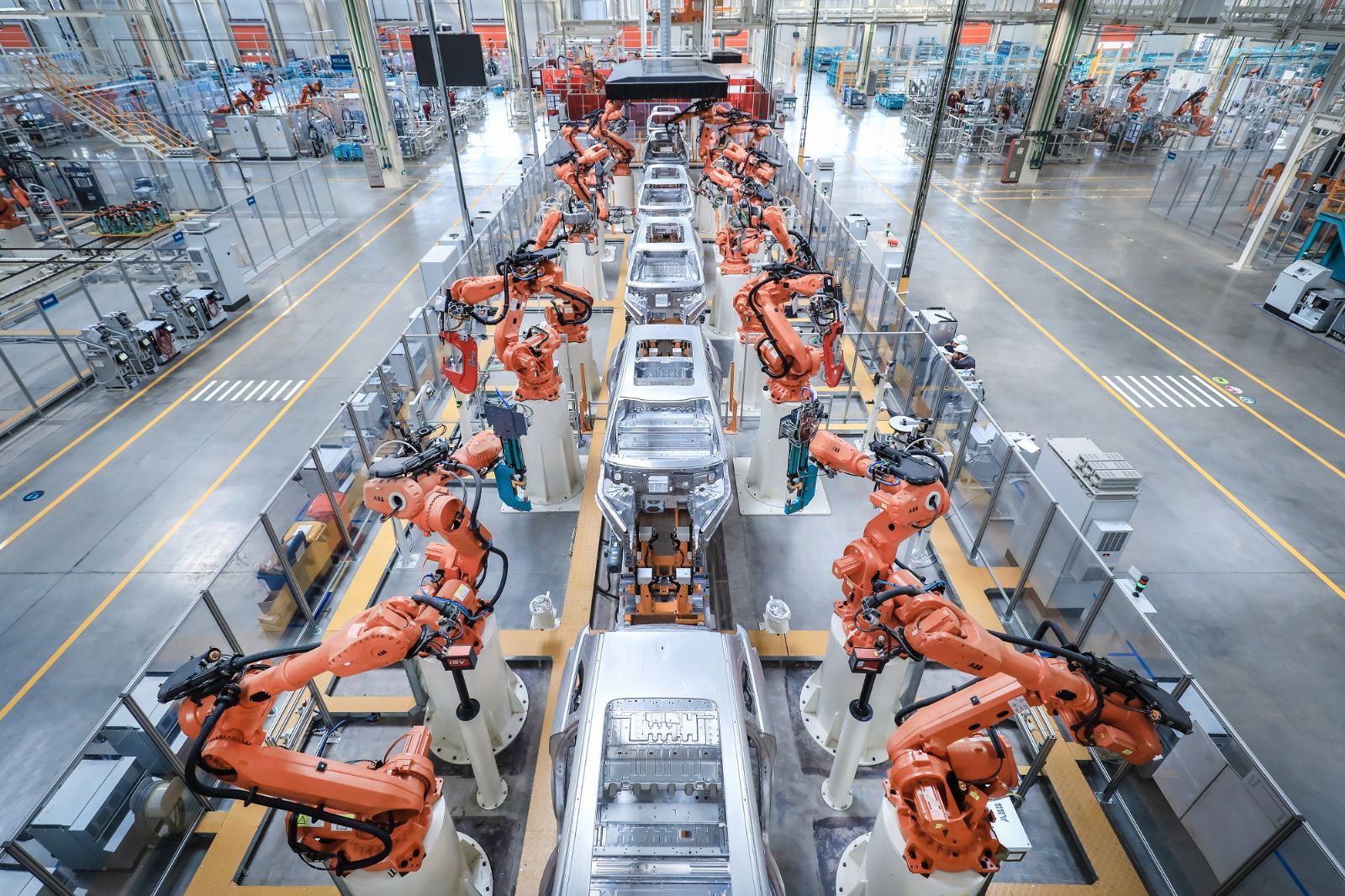

Litšoantšo tsa lihlahisoa

Lisebelisoa tsa lihlahisoa tsa Copper Tube Terminals

| Sebaka sa Tšimoloho: | Guangdong, China | Mmala: | silevera | ||

| Lebitso la Brand: | haocheng | Boitsebiso: | Koporo/ koporo | ||

| Nomoro ea Mohlala: | 129396001 | Kopo: | Lisebelisoa tsa lapeng. Likoloi. Lipuisano. Matla a macha. Lebone | ||

| Mofuta: | PCB welding terminal | Sephutheloana: | Mabokose a Tloaelehileng | ||

| Lebitso la sehlahisoa: | PCB welding terminal | MOQ: | 10000 li-PC | ||

| Phekolo ea sefahleho: | customisable | Ho paka: | 1000 li-PC | ||

| Sebaka sa marang-rang: | customisable | Boholo: | customisable | ||

| Nako ea ho etella pele: Nako ea nako ho tloha ha odara e beoa ho isa ho e rometsoeng | Bongata (likotoana) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Nako ea ho tsamaisa (matsatsi) | 10 | 15 | 30 | Ho buisanoa | |

Melemo ea li-terminals tsa Copper Tube

1.Tlhahiso e Ntle ea Motlakase

E entsoe ka koporo e phahameng ea bohloeki ho netefatsa phallo e tsitsitseng ea hona joale le ho hanyetsa ho fokolang.

2.Superior Solderability

Boreleli bo boreleli le litekanyo tse nepahetseng li ts'ehetsa solder ea matsoho le ea othomathiki.

3.Strong Mechanical Stability

E fana ka fixation e ka tšeptjoang ho PCB, esita le tlas'a vibrate kapa khatello ea mochine.

4.Corrosion Resistance

Ho khetha tin kapa nickel plating ho sireletsa khahlanong le oxidation le ho matlafatsa nako e telele.

5.High Thermal Endurance

E mamella mocheso o phahameng oa soldering nakong ea reflow le wave soldering process.

6.Moqapi o sebetsang hantle le oa sebaka

Mehato e nyane e loketseng meaho ea potoloho e teteaneng le lisebelisoa tsa elektroniki tsa sejoale-joale.

7, Libopeho le boholo bo ka khonehang

E fumaneha ka mefuta e mengata ho lumellana le mekhoa e fapaneng ea PCB le litlhoko tsa hajoale.

8.Chelete e sebetsang le e tšoarellang nako e telele

E fokotsa litšenyehelo tsa tlhokomelo le tse ncha ka lebaka la ts'ebetso e tsitsitseng ka nako.

Lilemo tse 18+ tsa Copper Tube Terminals Cnc Machining Experience

• Liphihlelo tsa R&D tsa Lilemo tse 18 nakong ea selemo, setempe sa tšepe le likarolo tsa CNC.

• Boenjiniere ba litsebo le botekgeniki ho netefatsa boleng.

• Ho tsamaisoa ka nako

• Boiphihlelo ba lilemo tsa ho sebelisana le lihlahisoa tse holimo.

• Mefuta e fapaneng ea mochini oa tlhahlobo le tlhahlobo bakeng sa netefatso ea boleng.

Lisebelisoa

Likoloi

lisebelisoa tsa lapeng

libapalisoa

li-switches tsa matla

lihlahisoa tsa elektronike

mabone a deske

lebokose la kabo E sebetsa ho

Lithapo tsa motlakase ka lisebelisoa tsa kabo ea matla

Lithapo tsa motlakase le lisebelisoa tsa motlakase

Khokahano bakeng sa

sefefo sa maqhubu

Likoloi tse ncha tsa matla

Moetsi oa likarolo tsa lisebelisoa tsa thepa e le 'ngoe

Puisano ea Bareki

Utloisisa litlhoko tsa bareki le litlhaloso tsa sehlahisoa.

Moqapi oa Sehlahisoa

Etsa moralo o ipapisitseng le litlhoko tsa bareki, ho kenyeletsoa lisebelisoa le mekhoa ea tlhahiso.

Tlhahiso

Etsa sehlahisoa u sebelisa mekhoa e nepahetseng ea tšepe e kang ho itšeha, ho cheka, ho sila, joalo-joalo.

Kalafo ea Bokaholimo

Sebelisa lisebelisoa tse nepahetseng tsa bokaholimo joalo ka ho fafatsa, electroplating, kalafo ea mocheso, jj.

Taolo ea Boleng

Hlahloba le ho netefatsa hore lihlahisoa li finyella litekanyetso tse boletsoeng.

Tsamaiso

Lokisetsa lipalangoang bakeng sa ho isoa ka nako ho bareki.

Tšebeletso ea ka mor'a thekiso

Fana ka tšehetso le ho rarolla mathata afe kapa afe a bareki.

LBH

A: Ka mor'a hore theko e netefatsoe, u ka kopa lisampole ho hlahloba boleng ba lihlahisoa tsa rona. Haeba u hloka feela sampuli e se nang letho ho hlahloba moralo le boleng. Ha feela o ntse o ka khona ho reka thepa e potlakileng, re tla u fa lisampole mahala.

A: Re atisa ho qotsa pele ho lihora tse 24 ka mor'a ho fumana potso ea hau. Haeba u potlakile ho fumana theko, ka kopo, re tsebise lengolo-tsoibila la hau hore re tle re etelletse pele potso ea hau.

A: E itšetlehile ka bongata ba taelo le ha u beha taelo.FAQ

A: Re feme.