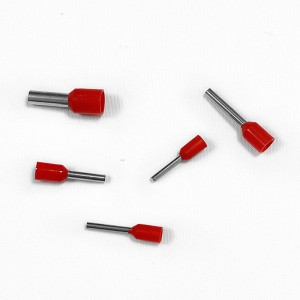

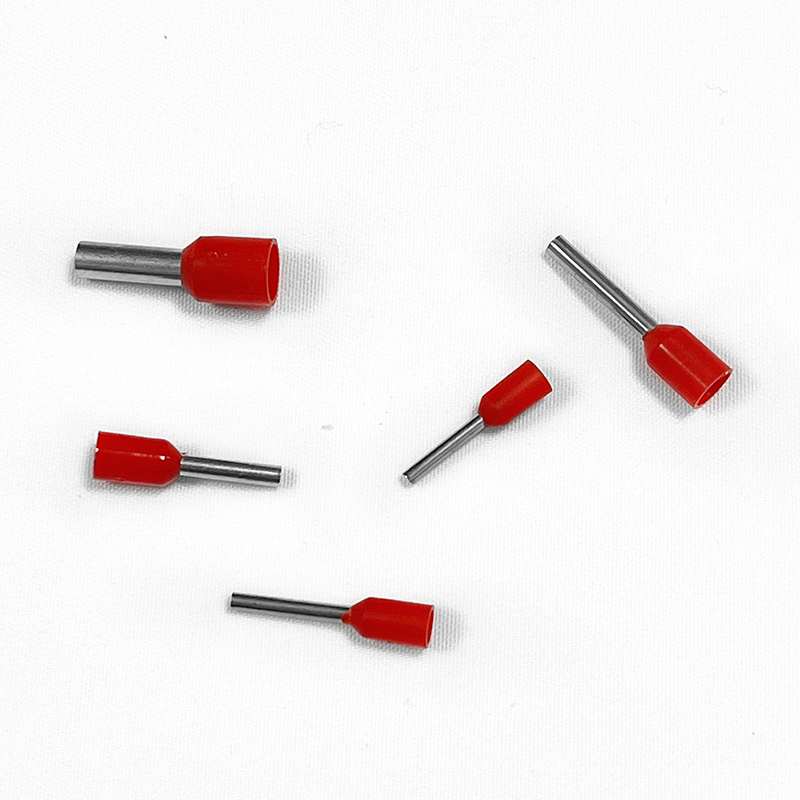

cord end ferrules Tubular terminal European style tubular copper wire lug

Product parameters

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper/brass | ||

| Model Number: | 0.34mm²-150mm² | Application: | Wire Connecting | ||

| Type: | VE series Insulated terminals |

Package: | 1000PCS/bag | ||

| Product name: | VE terminal | MOQ: | 1000 PCS | ||

| Surface treatment: | tin-plating | Packing: | 1000 PCS | ||

| Wire range: | 1.9-23.4 | Size: | 11-53 | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 5 | 7 | 10 | 15 | |

Advantage

Excellent conductive properties

Copper is an excellent conductor with high-quality properties that ensure stable and efficient current transmission.

Good thermal conductivity

Copper's high thermal conductivity allows it to rapidly disperse the heat produced by current, contributing to the stability and safety of the terminal block.

High strength and corrosion resistance

Copper terminals are characterized by their exceptional strength, resistance to corrosion, and ability to endure high loads and diverse environmental conditions, while also demonstrating resilience against oxidation and corrosion.

Stable connection

The copper terminal blocks utilize threaded or plug-in connections, ensuring secure and reliable wire connections that are resistant to loosening or poor contact.

Various specifications and types

Copper terminal blocks are offered in a range of specifications and types, catering to various wire sizes and connection requirements to meet diverse application needs.

Easy to install and maintain:

The uncomplicated and user-friendly design of the copper terminal blocks facilitates effortless installation and maintenance, rendering them suitable for deployment in a wide range of settings including residential, industrial, and commercial environments.

Sourced directly from the manufacturer, our products are available in bulk with competitive pricing and comprehensive options for customization. Crafted with premium red copper for optimal conductivity and longevity, our strict production processes ensure excellent electricalperformance and resistance to corrosion.

The acid washing treatment provides resistance to corrosion and oxidation, while the electroplating process with environmentally friendly high-temperature tin offers enhanced conductivity, corrosion resistance, and durability.

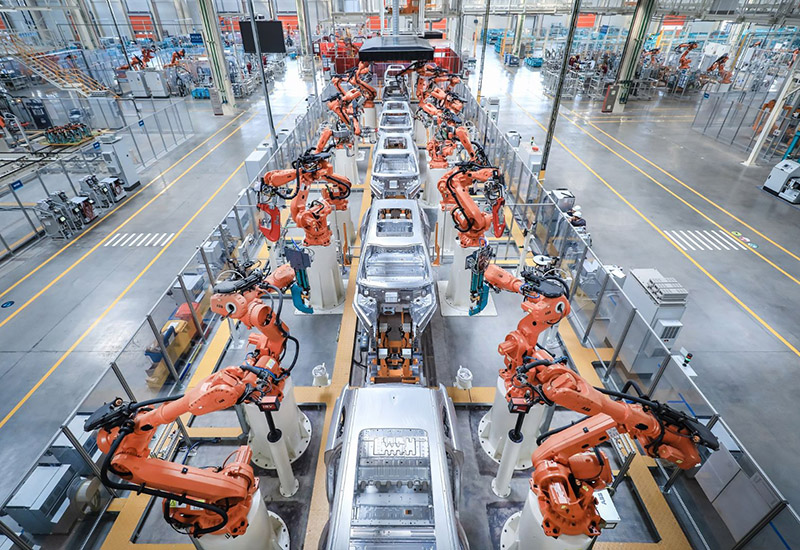

Applications

New energy vehicles

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

Customized service process

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

Corporate advantage

• 18 years of research and development expertise in springs, metal stamping, and CNC parts.

• Proficient and technically skilled engineering to uphold quality standards.

• Reliable on-time delivery.

• Extensive experience collaborating with top brands.

• Diverse array of inspection and testing machinery for quality assurance.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.