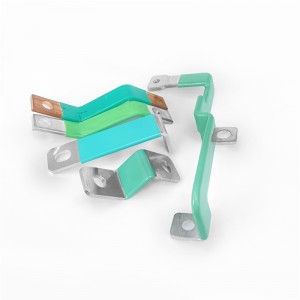

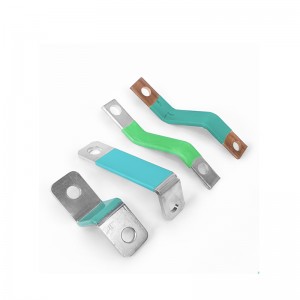

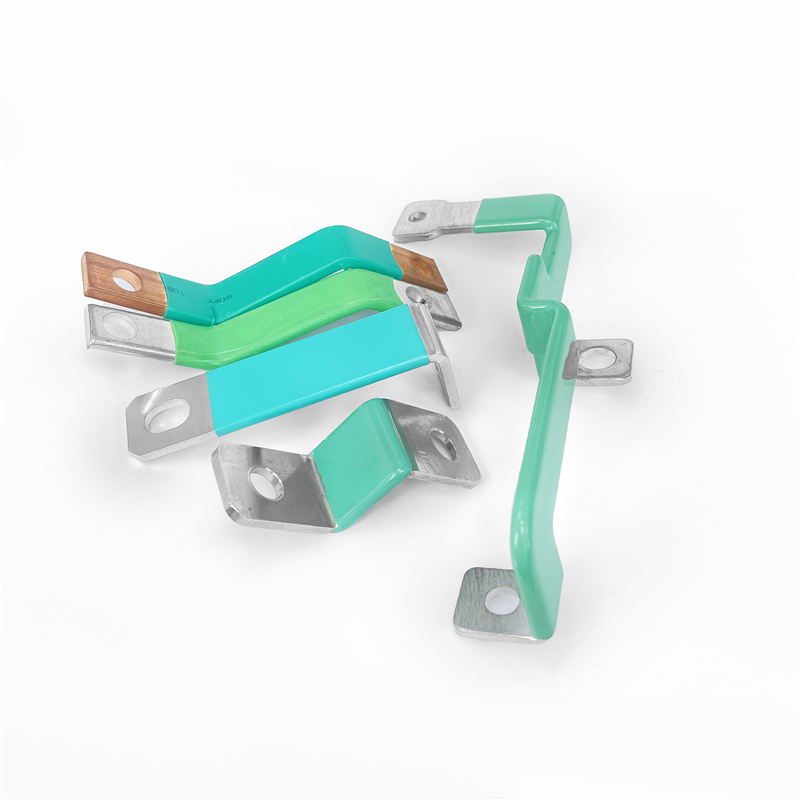

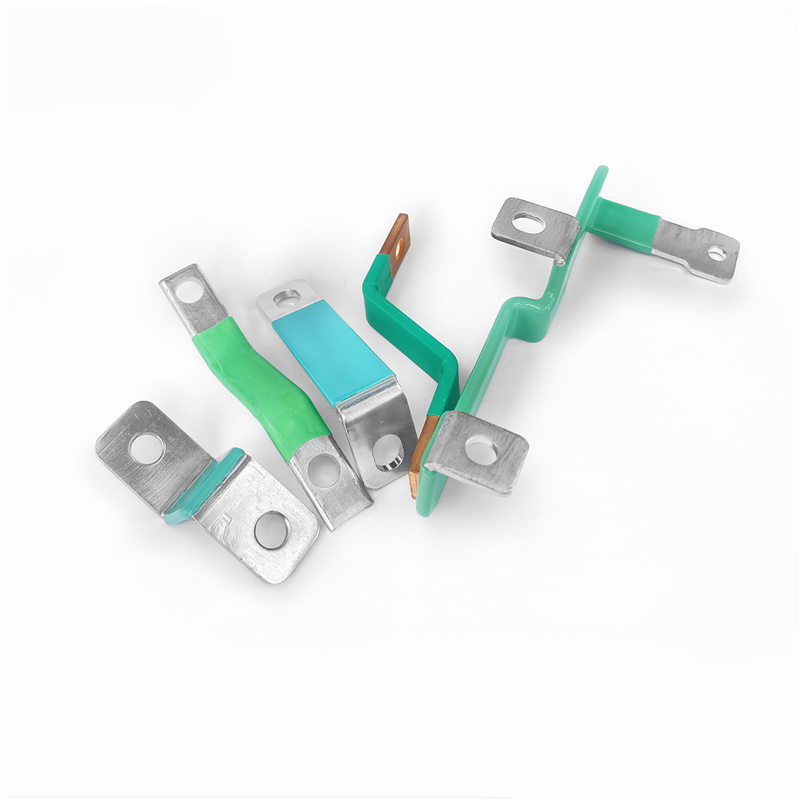

Insulating powder coated copper bars

Product parameters

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper | ||

| Model Number: | 10mm²-1000mm² | Application: | Wire Connecting | ||

| Type: | copper busbar | Package: | Standard Cartons | ||

| Product name: | Insulating powder coated copper bars |

MOQ: | 100 PCS | ||

| Surface treatment: | customizable | Packing: | 100 PCS | ||

| Wire range: | customizable | Size: | 10mm-2000mm | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantage

Excellent conductive properties

Made of high-quality pure copper material, it ensures excellent conductivity, effectively reduces transmission loss, and improves charging efficiency.

Good thermal conductivity

The insulation material of the sprayed busbar is tightly adhered to the copper busbar, which is beneficial for the heat dissipation of the copper conductor. Compared to traditional heat pipe solutions, it has better heat dissipation performance;

High strength and corrosion resistance

The insulation layer thickness of the sprayed busbar can withstand a voltage withstand test of 380V-15000VAC from 0.1-3mm;The coated busbar can pass rigorous tests such as hundred grid, impact, vibration, high and low temperature aging, etc;The effective lifespan of the spraying busbar is greater than 150000 hours;

Stable connection

The insulated powder coated copper busbar adopts threaded or plug-in connections to ensure tight and reliable wiring, and is not easy to loosen or have poor contact.

Various specifications and types:

Insulated powder coated copper wire products can be of any shape, and the export port can be located in any part, saving installation space

Easy to install and maintain:

The insulated powder coated copper busbar has a simple and easy-to-use design, making it easy to install and maintain. They are suitable for various places such as homes, industry, and commerce. The export port can be located anywhere, saving installation space

Applications

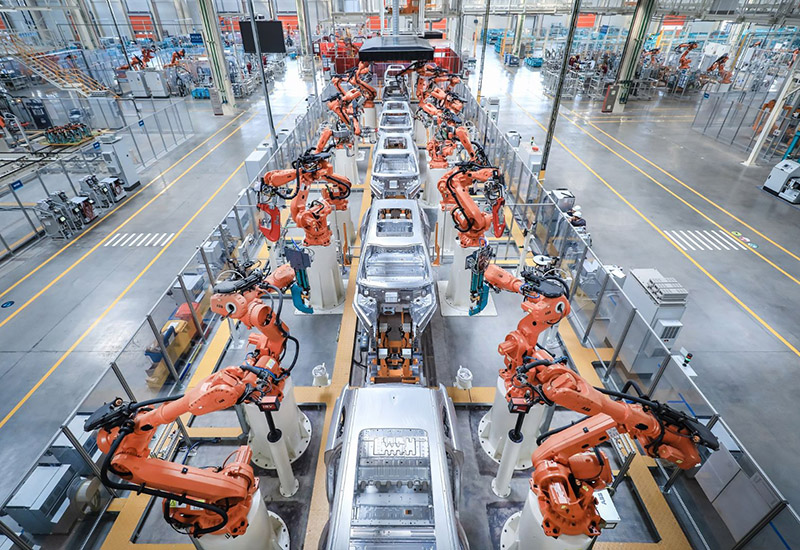

New energy vehicles

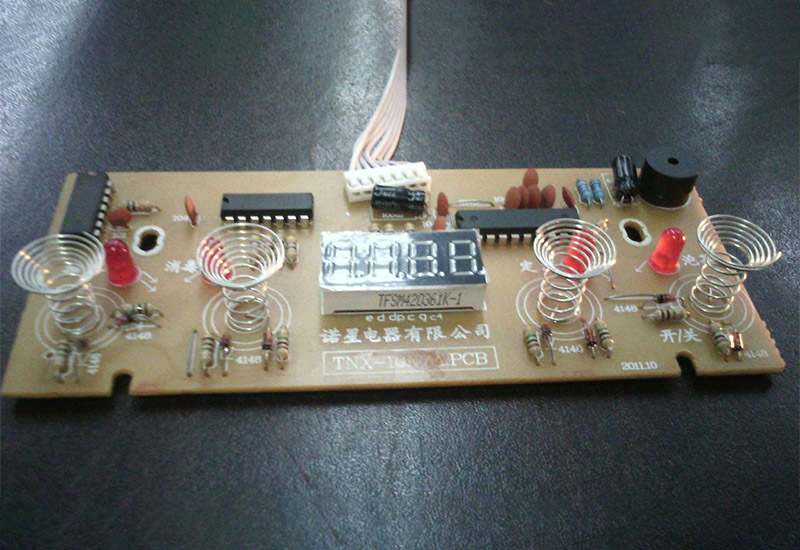

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

Customized service process

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

Corporate advantage

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.