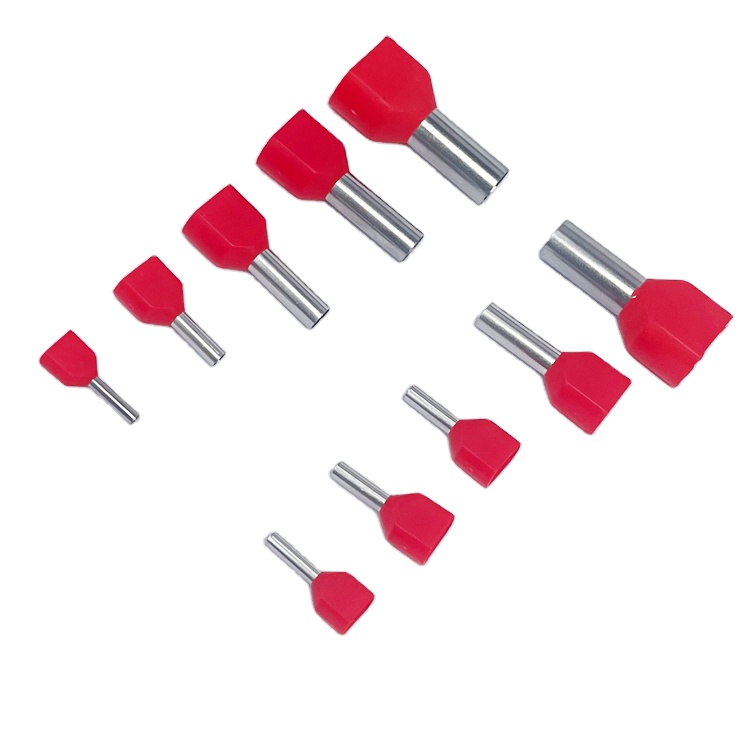

Twin wire end ferrules with plastic collar

Product parameters

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper/brass | ||

| Model Number: | 0.5mm²-16mm² | Application: | Wire Connecting | ||

| Type: | TE series Insulated terminals |

Package: | 1000PCS/bag | ||

| Product name: | TE terminal | MOQ: | 1000 PCS | ||

| Surface treatment: | tin-plating | Packing: | 1000 PCS | ||

| Wire range: | 0.5mm²-16mm² | Size: | 15-32 | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 5 | 7 | 10 | 15 | |

Advantage

Excellent conductive properties

Copper is a high-quality conductive material with excellent conductive properties, which can ensure stable and efficient current transmission.

Good thermal conductivity

Copper has good thermal conductivity and can quickly dissipate the heat generated by current, helping to maintain the stability and safety of the terminal block.

High strength and corrosion resistance

Copper terminals have high strength and corrosion resistance, can withstand high loads and various environments, and are not susceptible to oxidation and corrosion.

Stable connection

The copper terminal blocks adopt threaded connection or plug-in connection, which can ensure that the wire connection is tight and reliable, and is not prone to loosening or poor contact.

Various specifications and types

Copper terminal blocks are available in a variety of specifications and types, suitable for different wire sizes and connection needs, and can meet the needs of different application scenarios.

Easy to install and maintain:

The copper terminal blocks have a simple and easy-to-use design, which makes them easy to install and maintain. They are suitable for use in various places such as homes, industries and businesses.

Directly supplied by the manufacturer, with a large quantity, excellent price, and complete specifications, supporting customization.

Selected high-quality red copper with good conductivity, Adopting high-purity T2 copper rod for pressing, strict annealing process, good electrical performance, good resistance to electrochemical corrosion, and long service life.

Acid washing treatment, not easy to corrode and oxidize

Electroplating environmentally friendly high-temperature tin, with higher conductivity, corrosion resistance, and durability.

Applications

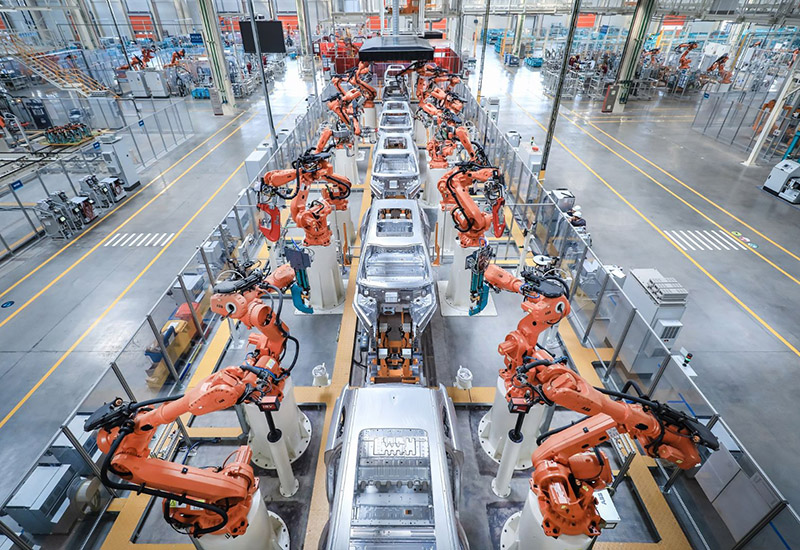

New energy vehicles

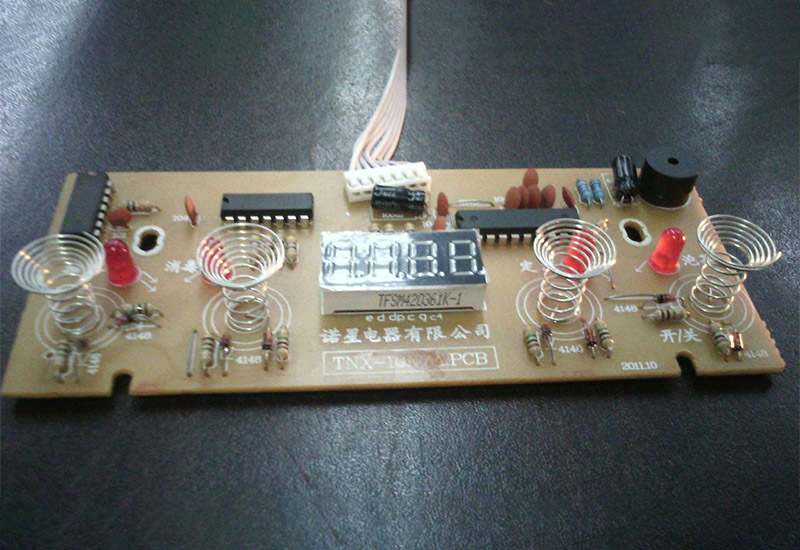

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

Customized service process

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

Corporate advantage

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.