Flexible copper busbar

Product pictures

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | Red/Silver | ||

| Brand Name: | haocheng | Material: | copper | ||

| Model Number: | Application: | Home appliances. Automobiles. Communications. New energy. Lighting |

|||

| Type: | Soft copper busbar | Package: | Standard Cartons | ||

| Product name: | Soft copper busbar | MOQ: | 10000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | customizable | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 25 | 35 | 45 | To be negotiated | |

Advantages of Copper Tube Terminals

Flexible copper busbars are highly adaptable power distribution components designed to carry large currents while allowing movement, vibration absorption, and efficient installation in confined or dynamic environments. They are increasingly used in electric vehicles, power electronics, renewable energy systems, and industrial equipment, where both electrical performance and mechanical flexibility are critical.

One of the key advantages of flexible copper busbars is their exceptional flexibility. Constructed from multiple layers of thin copper foils or braided copper strips, they can bend, twist, or compress without cracking or losing conductivity. This makes them ideal for applications where thermal expansion, mechanical vibration, or compact installation space is a concern. Unlike rigid conductors, flexible busbars easily accommodate movement and misalignment between components, reducing stress on terminals and joints.

In terms of electrical performance, flexible copper busbars offer excellent conductivity due to the use of high-purity copper. They are capable of carrying high currents with minimal power loss, making them highly efficient for demanding applications such as battery modules, inverters, switchgear, and DC distribution systems. The multi-layer or laminated structure also helps in reducing the skin effect and optimizing current distribution across the conductor.

Another major advantage is improved thermal management. The large surface area of flexible copper busbars helps dissipate heat more efficiently compared to round cables, which is crucial in high-current environments. Many designs also integrate insulation layers or heat-resistant coatings, which enhance safety and allow for closer spacing between components.

Flexible copper busbars are also valued for their space-saving and lightweight characteristics. Their flat profile and customized shape allow for denser, cleaner layouts within control cabinets or battery packs. This is especially beneficial in electric vehicles and compact power systems where every millimeter counts.

From a manufacturing standpoint, flexible busbars offer excellent design flexibility. They can be custom-shaped, punched, welded, or terminated to fit the specific requirements of any application. Whether it’s for a straight run, a 3D bend, or a twisted configuration, they can be produced with high precision and repeatability.

In summary, flexible copper busbars deliver the perfect combination of mechanical flexibility, electrical efficiency, thermal reliability, and design adaptability, making them an essential component in modern high-performance electrical systems.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

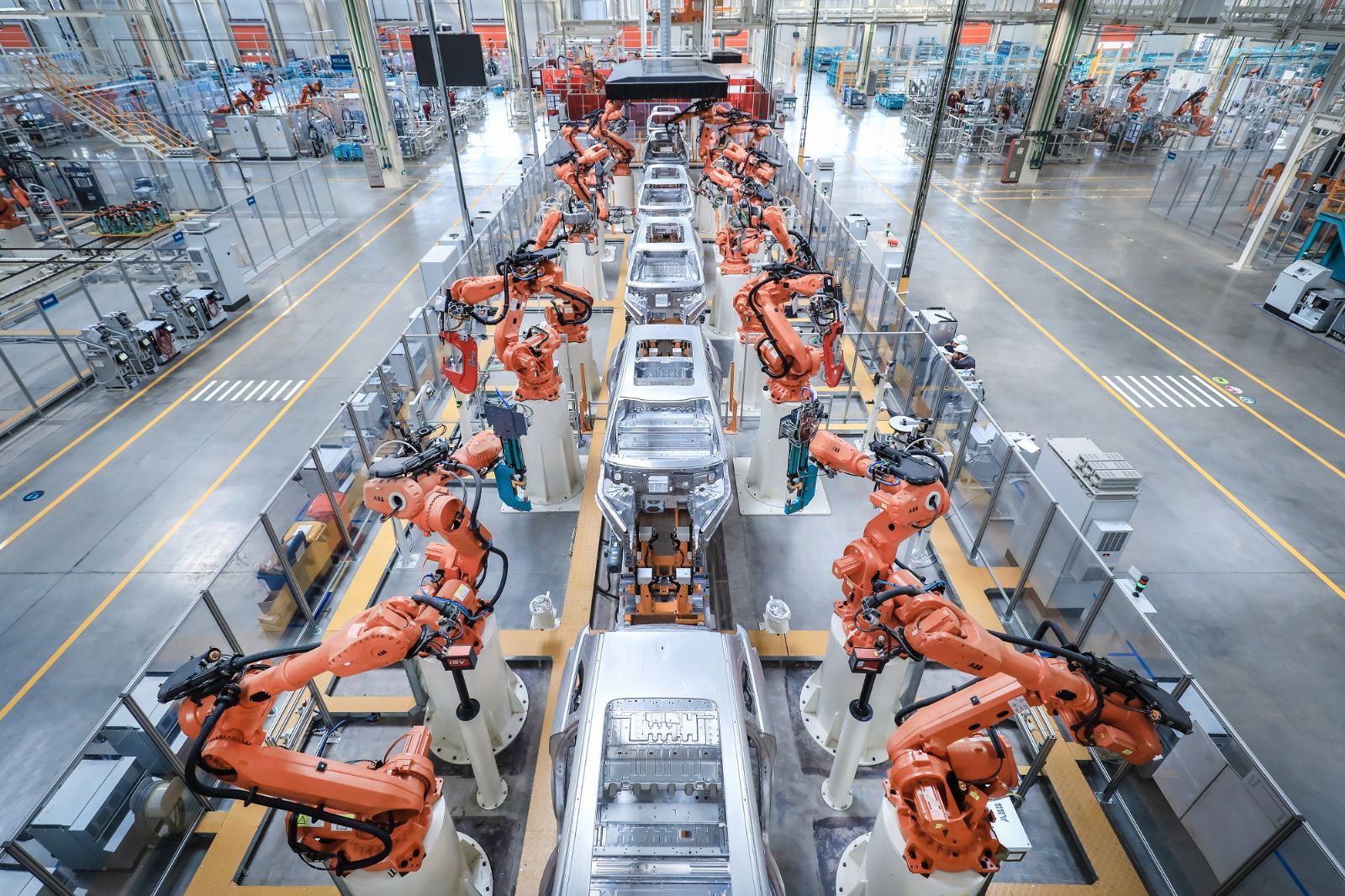

Applications

Automobiles

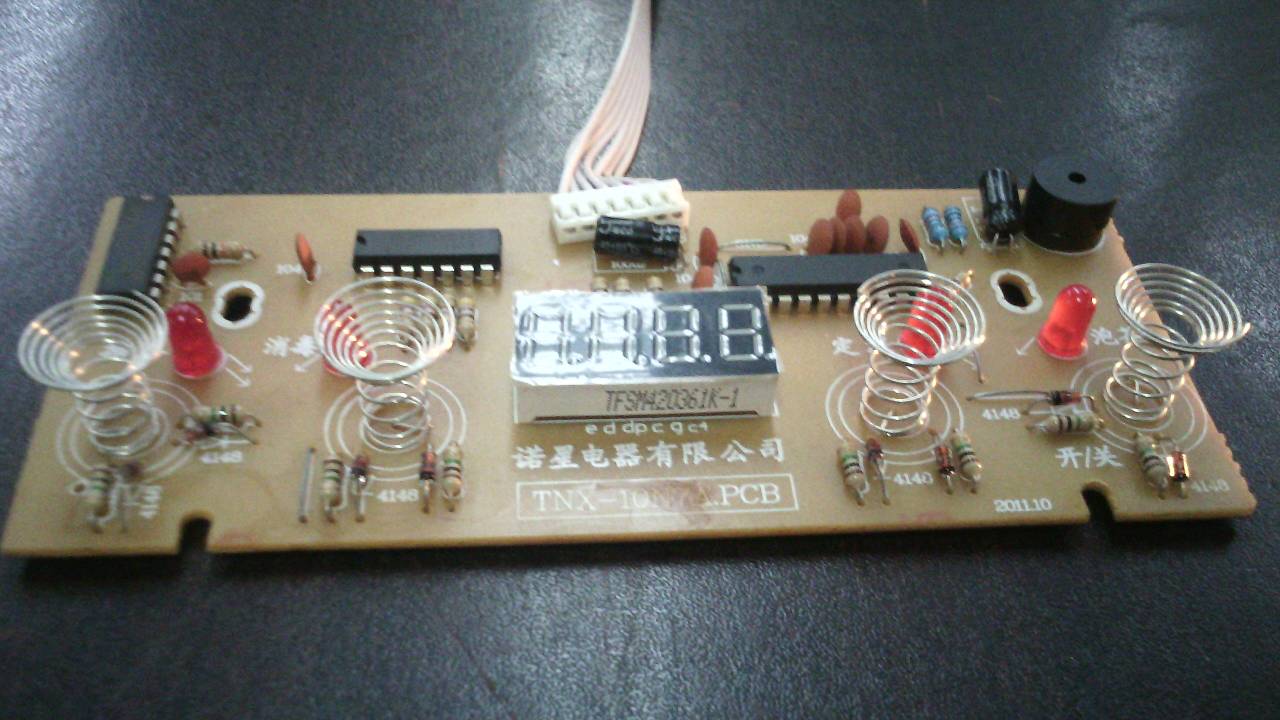

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: It depends on the order quantity and when you place the order.