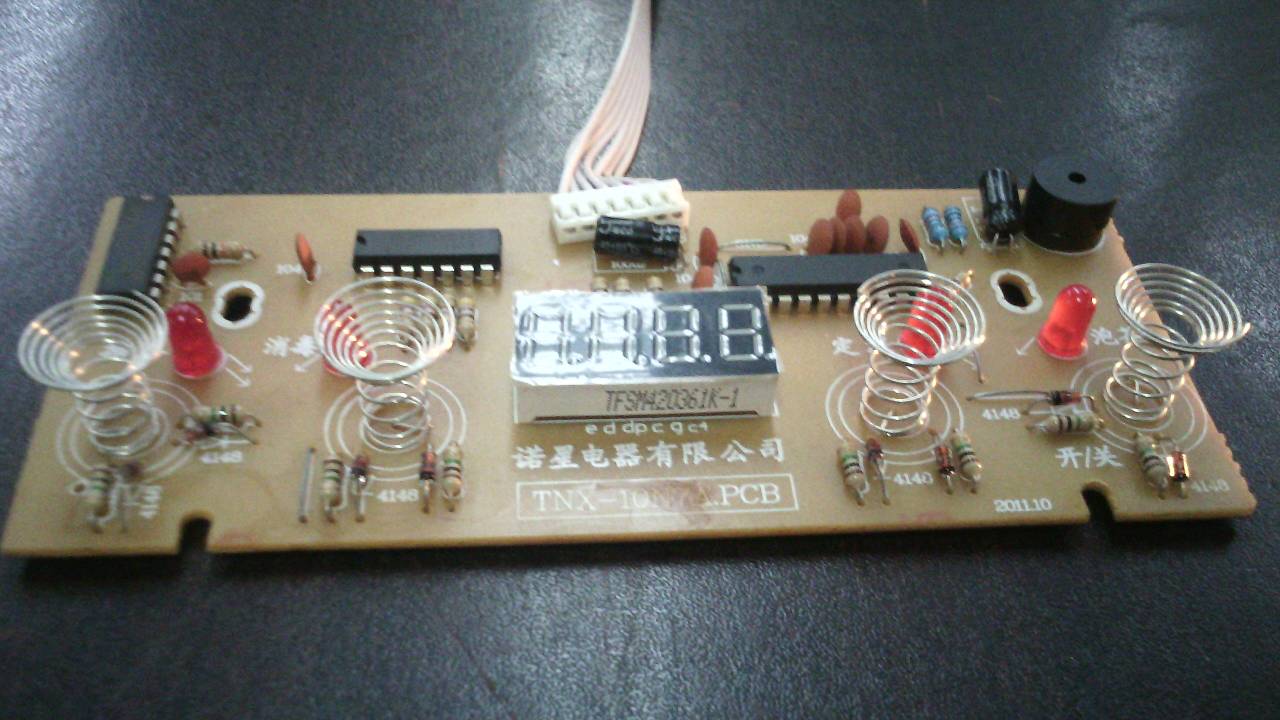

High-Conductivity Copper Terminals for PCB Soldering Applications

Product pictures

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper/brass | ||

| Model Number: | 129396001 | Application: | Home appliances. Automobiles. Communications. New energy. Lighting |

||

| Type: | PCB welding terminal | Package: | Standard Cartons | ||

| Product name: | PCB welding terminal | MOQ: | 10000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | customizable | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

1.Excellent Electrical Conductivity

Made of high-purity copper to ensure stable current flow and minimal resistance.

2.Superior Solderability

Smooth surface and precise dimensions support both manual and automated soldering.

3.Strong Mechanical Stability

Provides reliable fixation on the PCB, even under vibration or mechanical stress.

4.Corrosion Resistance

Optional tin or nickel plating protects against oxidation and enhances durability.

5.High Thermal Endurance

Withstands high soldering temperatures during reflow and wave soldering processes.

6.Compact and Space-Efficient Design

Small footprint suitable for dense circuit layouts and modern electronics.

7,Customizable Shapes and Sizes

Available in multiple forms to fit diverse PCB layouts and current requirements.

8.Cost-Effective and Long-Lasting

Reduces maintenance and replacement costs due to stable performance over time.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

Automobiles

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.FAQ

A: We are a factory.