New energy soft copper busbar

Product pictures

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | Red/Silver | ||

| Brand Name: | haocheng | Material: | copper | ||

| Model Number: | Application: | Home appliances. Automobiles. Communications. New energy. Lighting |

|||

| Type: | Soft copper busbar | Package: | Standard Cartons | ||

| Product name: | Soft copper busbar | MOQ: | 10000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | customizable | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 25 | 35 | 45 | To be negotiated | |

Advantages of Copper Tube Terminals

Soft copper busbars are increasingly used in new energy applications such as electric vehicles (EVs), energy storage systems (ESS), solar inverters, and charging infrastructure. These busbars, made of high-purity annealed copper, offer a unique combination of flexibility, conductivity, and thermal performance, making them ideal for compact and high-efficiency power systems.

One of the key advantages of soft copper busbars is their high electrical conductivity. Manufactured from oxygen-free or electrolytic tough pitch (ETP) copper, they can carry large currents with minimal resistance. This efficiency reduces power loss and improves overall energy utilization—crucial for applications like EV battery packs or renewable energy converters where energy efficiency is directly linked to performance and range.

Another major benefit is mechanical flexibility. Soft copper busbars are thinner and more pliable than rigid or laminated busbars, allowing them to easily adapt to tight installation spaces or complex 3D routing paths. This flexibility makes them highly suitable for dynamic environments, such as in electric vehicles, where vibrations and thermal expansion are frequent. They can effectively absorb mechanical stress, reducing the risk of failure at connection points.

Thermal management is another strength. Soft copper’s excellent thermal conductivity enables rapid heat dissipation, which helps prevent hot spots in high-current areas. This contributes to the stability and long-term reliability of the entire system. In EVs and power electronics, better thermal performance directly supports higher power density and more compact design.

Moreover, soft copper busbars are often paired with insulation layers such as PVC, PET, or epoxy coating to provide enhanced safety, voltage isolation, and mechanical protection. This allows for tighter component layouts and helps meet high-voltage requirements, especially in automotive and industrial settings.

From a production standpoint, soft copper busbars are highly customizable. They can be easily punched, bent, or layered into specific shapes and dimensions, enabling tailored designs for each application. Whether used for interconnection between battery modules or power units, they offer precise, cost-effective integration.

In summary, new energy soft copper busbars deliver outstanding advantages in conductivity, flexibility, heat dissipation, and space efficiency. Their adaptable nature and performance characteristics make them an essential component in the future of clean, efficient energy systems.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

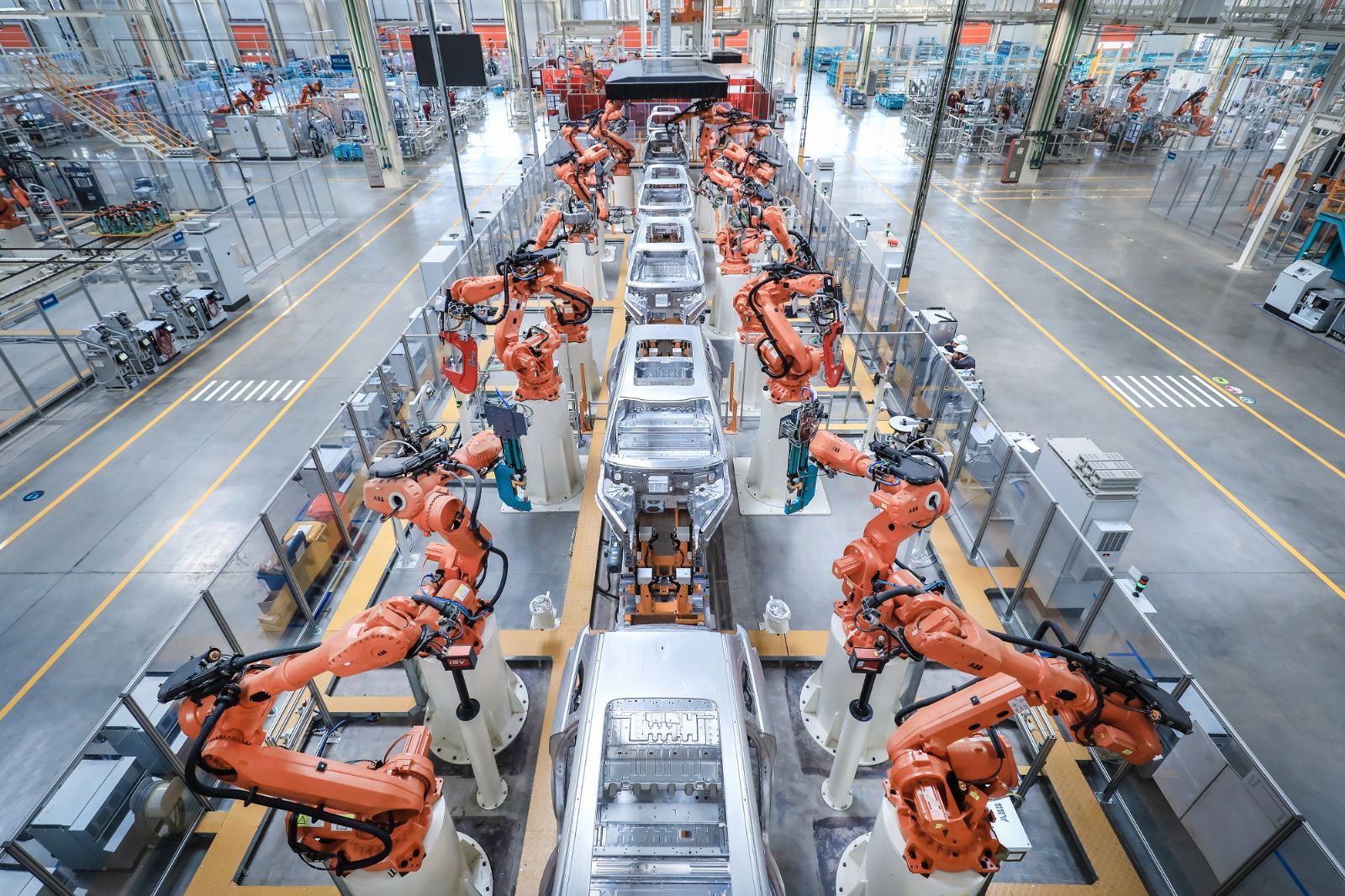

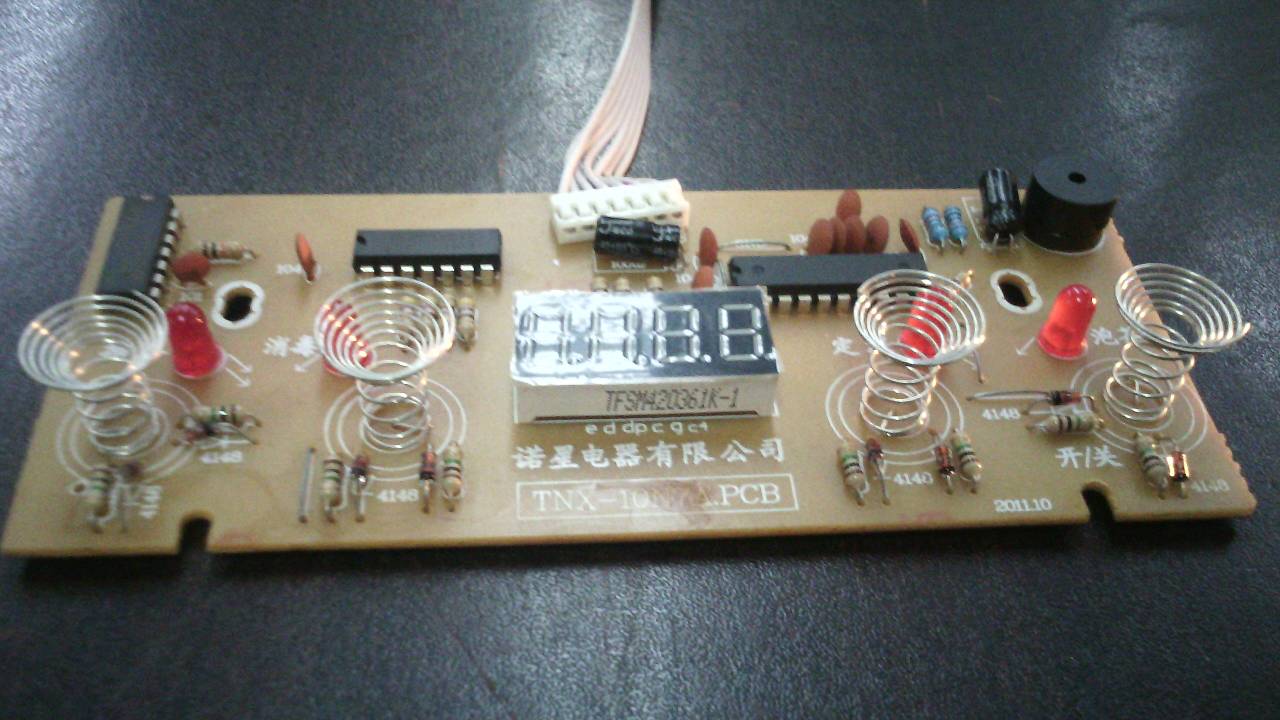

Applications

Automobiles

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: It depends on the order quantity and when you place the order.