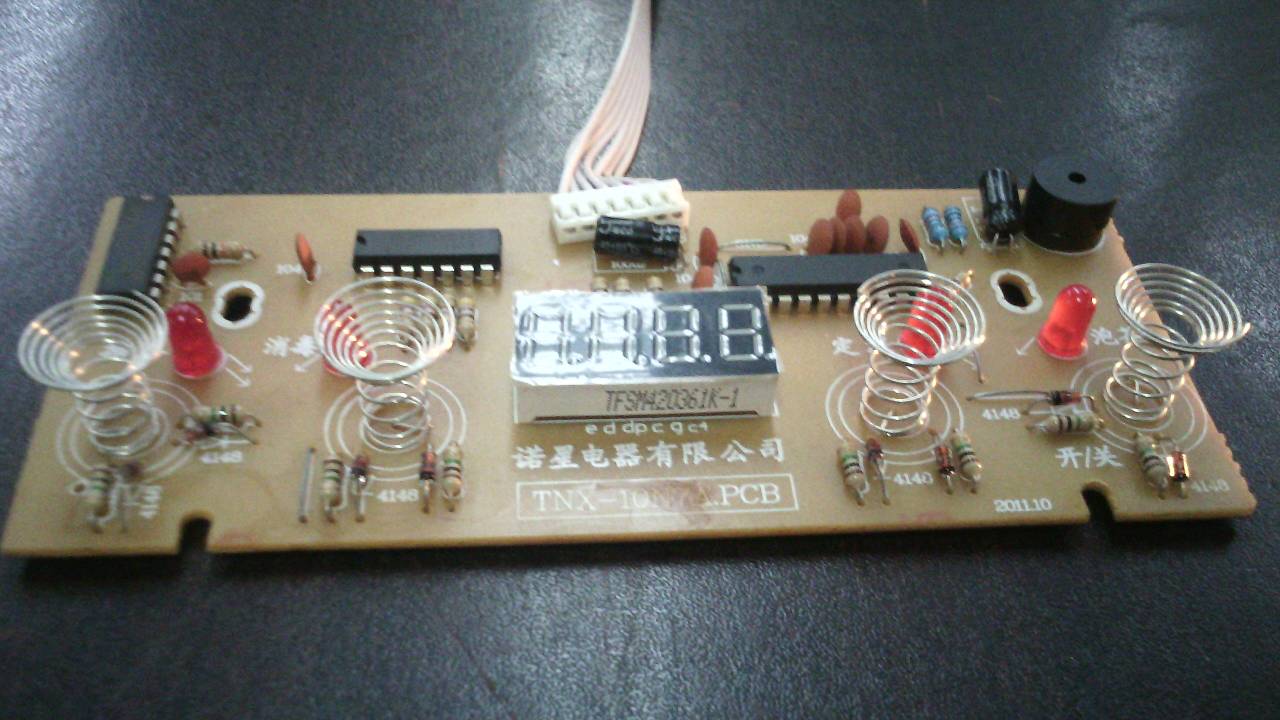

PCB4 Ping soldering terminal

Product pictures

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper/brass | ||

| Model Number: | 630009001 | Application: | Home appliances. Automobiles. Communications. New energy. Lighting |

||

| Type: | PCB welding terminal | Package: | Standard Cartons | ||

| Product name: | PCB welding terminal | MOQ: | 10000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | customizable | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

1.Excellent Electrical Conductivity: Made from high-conductivity brass or copper, ensuring efficient current transmission with minimal heat generation, suitable for high-current or high-frequency applications.

2.Reliable and Firm Soldering: The four-pin design enhances stability on the PCB, compatible with wave soldering or manual soldering, ensuring strong and durable solder joints.

3.Compact Structure, Space-Saving: Small and compact, ideal for high-density mounting, especially in miniaturized or complex electronic modules.

4.Corrosion-Resistant and Durable: Surface plating options such as tin or nickel enhance oxidation resistance, significantly extending product life and ensuring reliability in various environments.

5.Eco-Friendly and Safe: Compliant with RoHS and other international environmental standards, free of hazardous substances, suitable for export and high-end electronics.

6.High Compatibility: Standardized design fits a wide range of PCBs and connector systems; OEM/ODM customization available to meet specific application needs.

7.This terminal is an ideal solution for achieving efficient electrical connectivity and mechanical stability, widely used in household appliances, new energy systems, and power control applications.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

Automobiles

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: We are a factory.