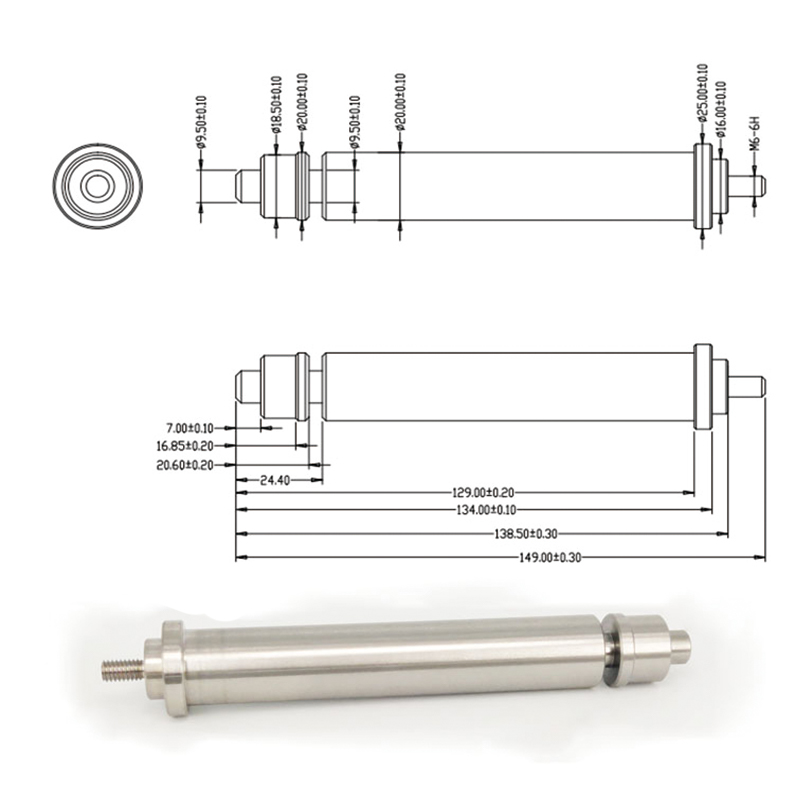

Stainless steel shaft

Product pictures

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | SS304 | ||

| Model Number: | Application: | Home appliances. Automobiles. Communications. New energy. Lighting |

|||

| Type: | Stainless steel shaft | Package: | Standard Cartons | ||

| Product name: | Stainless steel shaft | MOQ: | 10000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | customizable | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 25 | 35 | 45 | To be negotiated | |

Advantages of Copper Tube Terminals

1. Reliable electrical connection

Low contact resistance: The terminals are made of highly conductive materials (such as copper alloy) to ensure stable current transmission and reduce energy loss.

Strong welding: The welding design ensures a firm connection between the terminal and the PCB board, reduces the risk of cold welding and broken welding, and improves product durability.

2. High mechanical strength

Good vibration resistance: Suitable for equipment that needs to withstand vibration and impact, such as industrial control, power modules, etc.

High plug-in life: Suitable for applications with frequent plug-in and pull-out, improving the durability and stability of the terminals.

3. High temperature tolerance

High temperature resistant materials: Some terminals are tin-plated or gold-plated, and can withstand high temperature welding processes (such as wave soldering and reflow soldering).

Suitable for harsh environments: Suitable for environments with large temperature changes, such as automotive electronics, power equipment, etc.

4. Strong compatibility

Adapt to different PCB thicknesses: Terminals of various specifications can be provided according to different applications, and are suitable for various PCB boards.

Suitable for automated welding: Supports automated production processes such as SMT and DIP to improve production efficiency.

5. Multiple surface treatments available

Tin plating: improves welding performance, prevents oxidation, and improves corrosion resistance.

Gold plating: reduces contact resistance, improves oxidation resistance, and is suitable for high-end electronic products.

Silver plating: improves conductivity and high temperature resistance, and is suitable for high-power circuits.

6. Diversified structures and flexible applications

Multiple installation methods: such as straight plug, bend plug, surface mount, etc., can meet different PCB design requirements.

Different rated currents available: suitable for low current signal transmission or high current power supply applications.

7. Green and environmentally friendly

RoHS compliant: using environmentally friendly materials and complying with international environmental regulations.

Low-lead and lead-free soldering support: meet environmentally friendly production needs and are suitable for high-end markets.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

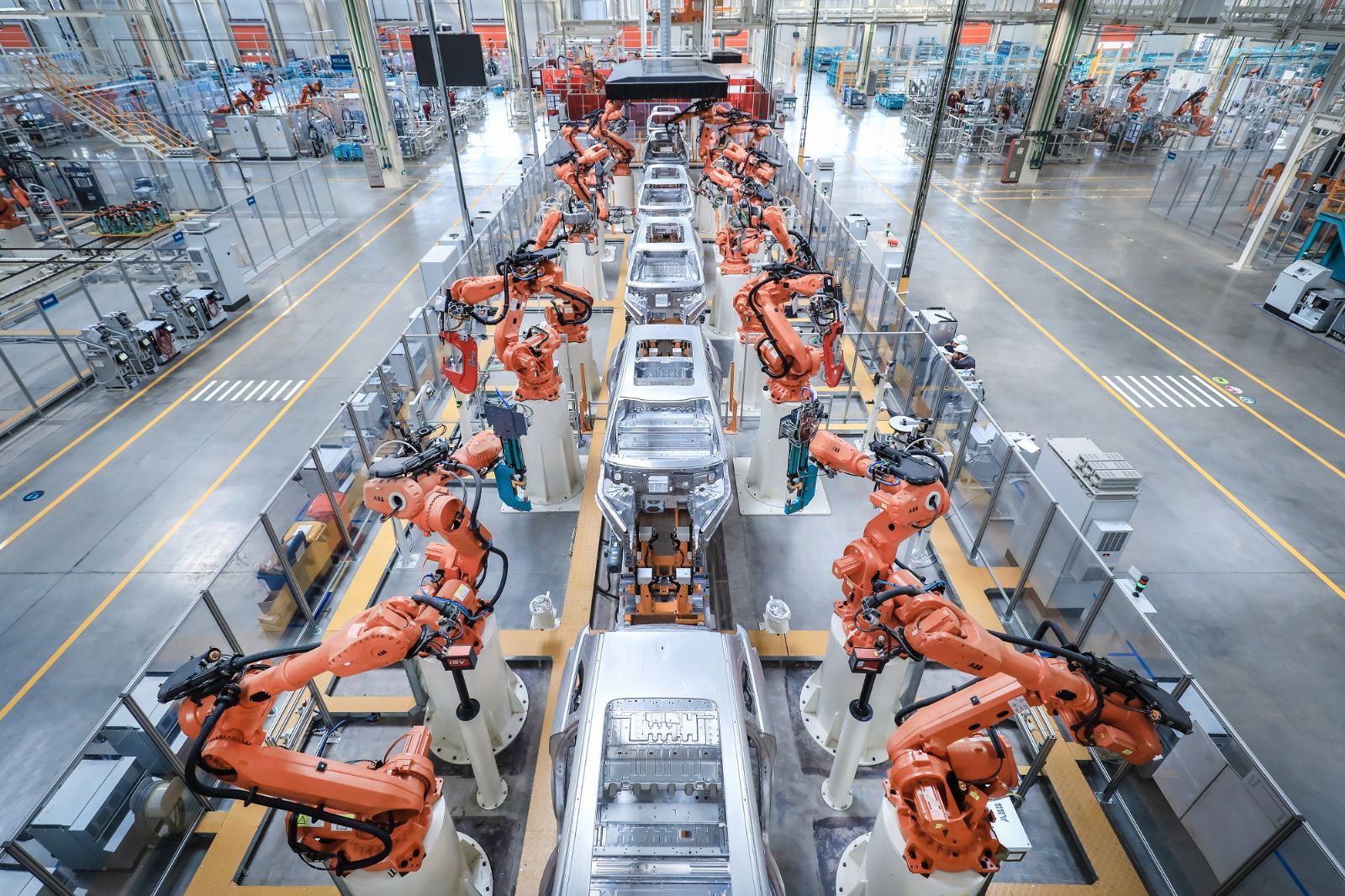

Applications

Automobiles

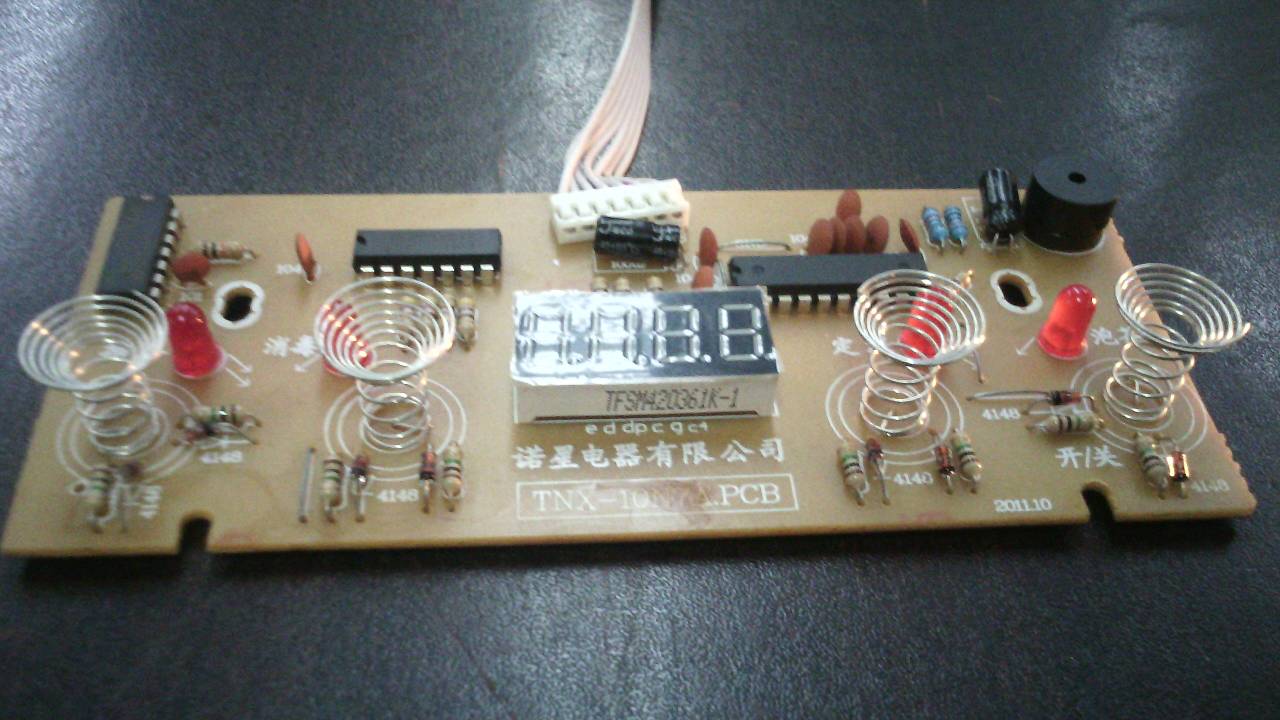

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.